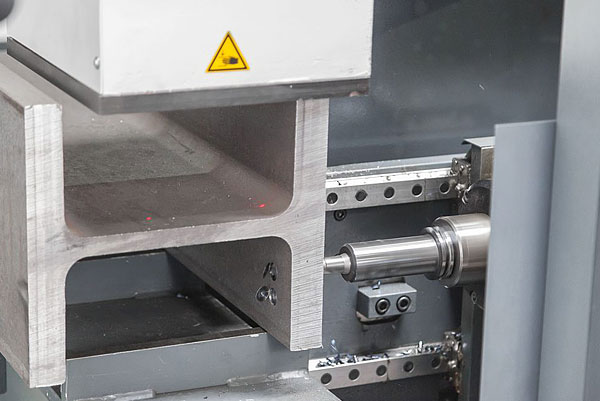

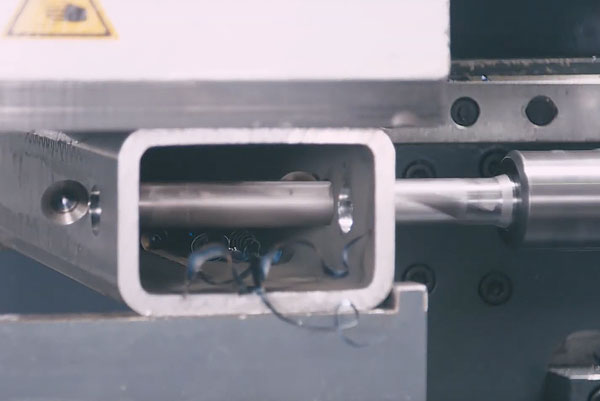

Cnc Drill Line Vent

Even for those with little or no computer or CNC experience, programming the CNC Drill Line is easy and intuitive.

FlexBeam is a brand new machine tool for producing steel profiles. It can be used to produce high-quality, cost-effectively and quickly. This machine can handle large-scale jobs and is an efficient option for small- to medium-sized fabrication shops.